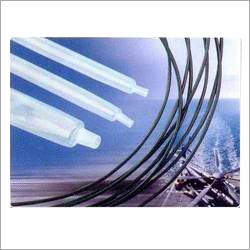

Thin Wall Flexible PVDF Tubing

Product Details:

- Product Type Thin Wall Flexible PVDF Tubing

- Material PVDF

- Application Industrial

- Color Clear, Black

- Click to View more

Thin Wall Flexible PVDF Tubing Price And Quantity

- 15 INR/Meter

- 50 Meter

Thin Wall Flexible PVDF Tubing Product Specifications

- Industrial

- Clear, Black

- Thin Wall Flexible PVDF Tubing

- PVDF

Thin Wall Flexible PVDF Tubing Trade Information

- Cash in Advance (CID), Cheque

- 1-7 Days

- Yes

- Free samples are available

- All India

Product Description

Capitalizing on the proficiency of our professionals, we are able to manufacture and export the large variety of Thin Wall Flexible PVDF Tubing. Our tubes are precisely made by utilizing high grade material sourced from reputed market vendors. These tubes are mostly applicable for the applications that require outstanding abrasion and high temperature resistance. Moreover, the provided Thin Wall Flexible PVDF Tubing is also helpful in protecting connection, terminals and solder joints.

Features:

- Glass type appeal

- Highly protective

- Long lasting

Further Details:

We source and offer superior quality thin wall flexible PVDF tubing (H-150K) which are excellent flame-retardant heat-shrinkable polyvinylidence fluoride tubes. Our tubing protects solder joints, terminals and connections from most industrial fuels, solvents and chemicals. The glass-like appearance enhances to inspect the mark on protected harness.

Specification:

- Minimum fully recovery temperature: 135C

- Approvals: UL, VW-1, File No E249362

- Meet: SAE-AMS-DTL-23053/18

- Standard color: Clear, Black

Technical Data

| Property | Test Method | Typical Data | |

| Operating temperature | IEC 216 | -55 C to 150 C | |

| Un-aged | Tensile strength | ASTM D 2671 | Min.30 MPa |

| Elongation | ASTM D 2671 | Min.150% | |

| After Aging | Elongation | 180 C, 168hrs. | Min.100% |

| Heat shock | 250 C, 4hr | No cracking | |

| Cold bend | -55 C, 4hr. | No cracking | |

| Dielectric Strength | UL224 | Min.2.5KV/1minute | |

| Volume resistance | ASTM D 876 | Min.10 cm | |

| Flammability | VW-1 | Pass | |

| Copper corrosion | 180 C, 168hrs | No corrosion | |

| Copper stability | 180 C, 168hrs | No sigh of Degradation | |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Heat Shrinkable Tubes' category